A sublimation machine is a versatile device used for creating high-quality, vibrant prints on various materials. It utilizes heat and pressure to detailed designs.

How Sublimation Machines Work

Sublimation machines utilize a heat transfer process to dye fabrics and materials. They convert solid dye into a gas without any liquid stage in between. The material then absorbs the gas, resulting in vibrant, long-lasting prints. With precise temperature and pressure control, these machines offer efficient and high-quality sublimation printing solutions.

Sublimation Process Explained

Sublimation machines are widely used in the printing industry to transfer high-quality, full-color designs onto various materials such as fabric, ceramics, and metal. The sublimation process involves turning a solid into a gas without going through the liquid state. This unique process results in vibrant and long-lasting prints that are resistant to fading and peeling.

Components Of A Sublimation Machine

A sublimation machine comprises several key components that work together to facilitate the process. These components include:

- Heat Press: The heat press is essential for heating the transfer paper and the printed material. It applies consistent and even heat and pressure to ensure proper sublimation.

- Thermal Transfer Paper: This specially coated paper holds the sublimation ink. When heat is applied, the ink on the transfer paper becomes a gas, allowing it to penetrate the material’s surface.

- Sublimation Ink: Sublimation ink is formulated to convert from a solid to a gas under heat and pressure. It is designed to bond with the material’s polymer fibers, producing vibrant and durable prints.

- Control Panel: The control panel allows users to adjust settings such as temperature, pressure, and time. These settings ensure optimal sublimation for different materials and designs.

- Heating Element: The heating element, usually made of heated plates or a drum, generates the heat required for sublimation. It efficiently transfers heat to the material and the transfer paper, enabling the ink to sublimate.

- Vacuum System: Some sublimation machines feature a vacuum system that removes air and moisture from the printing area. This system ensures proper contact between the transfer paper and the material, helping to achieve smooth and wrinkle-free prints.

By understanding the sublimation process and the components of a sublimation machine, you can harness the power of this technology to create stunning and long-lasting prints on a wide range of materials.

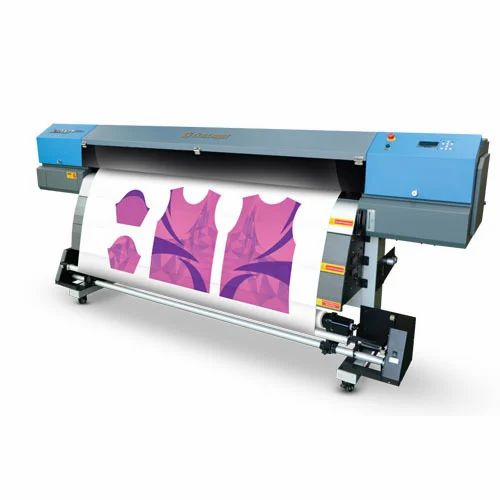

Types Of Sublimation Machines

Sublimation machines are essential tools for transferring vibrant and long-lasting designs onto various fabrics and materials. There are different types of sublimation machines available in the market, each catering to different needs and preferences. In this article, we will explore two popular types: Heat Press Sublimation Machines and 3D Vacuum Sublimation Machines.

Heat Press Sublimation Machines

Heat Press Sublimation Machines are versatile and widely used in the sublimation printing industry. As the name suggests, these machines apply heat and pressure to the design, facilitating ink transfer from the sublimation paper to the material. The process involves placing the sublimation paper face on the fabric and clamping it between heated plates. The heat and pressure cause the ink to turn into a gas, permeating the fabric’s fibers and producing a vibrant and durable print.

These machines are available in various sizes and configurations, allowing users to choose the one that best suits their needs. Some heat press sublimation machines are manual, requiring the user to apply the pressure manually, while others are automatic, providing consistent pressure without requiring manual adjustments. Additionally, some models have digital controls, allowing precise temperature and time settings for optimal results.

3d Vacuum Sublimation Machines

3D Vacuum Sublimation Machines are specifically designed for sublimating complex-shaped items. This type of machine is ideal for printing on curved surfaces, such as mugs, plates, phone cases, and other 3D objects. Unlike heat press machines, 3D vacuum machines use a combination of heat and vacuum pressure to transfer the ink to the material. The process involves placing the printed sublimation paper onto the object, which is then secured within the machine’s vacuum chamber. The machine applies heat evenly, while the vacuum pressure ensures that the design adheres perfectly to the curved surface, resulting in a seamless and professional-looking print.

These machines offer great versatility and allow businesses to expand their product offerings by personalizing various 3D items. With adjustable temperature, time, and pressure settings, users can easily achieve excellent results on different materials. Whether you are a small business owner or a DIY enthusiast, a 3D vacuum sublimation machine can add a new dimension to your creative projects and help you stand out in a competitive market.

Choosing The Right Sublimation Machine

Choosing the right machine is crucial for achieving high-quality and professional results in sublimation printing. Whether you are a beginner or an experienced user, finding the perfect sublimation machine requires careful consideration and an understanding of the features that best suit your needs. In this article, we will guide you through the process of selecting the right sublimation machine, covering the key considerations for beginners and the advanced features to look for.

Considerations For Beginners

If you are new to sublimation printing, there are a few important factors to consider when choosing a sublimation machine:

- Budget: Determine how much you are willing to invest in a sublimation machine. While various options are available on the market, setting a budget will help narrow down your choices.

- Size and Versatility: Consider the size and versatility of the machine. Will it fit into your workspace? Does it have the capability to handle different sizes of fabrics or materials?

- Ease of Use: Look for a sublimation machine that is user-friendly and comes with clear instructions. As a beginner, you want a machine that is easy to operate and requires minimal setup or calibration.

- Printing Speed: The printing speed of a sublimation machine is an important factor, especially if you anticipate high-volume printing. Look for a machine that offers fast printing without compromising on quality.

- Customer Support: Consider the availability and quality of customer support provided by the manufacturer. In case you encounter any issues or have questions, it is important to have reliable support to assist you.

Advanced Features To Look For

If you are an experienced user or planning to take your sublimation printing to the next level, here are some advanced features to look for in a sublimation machine:

- Higher Resolution: Look for a machine with higher print resolution for sharper and more detailed prints. This is particularly important if you plan on printing complex designs or photographs.

- Multiple Printing Options: Consider a sublimation machine that allows you to print on various materials such as fabrics, mugs, ceramic tiles, and more. This versatility expands your options and potential business opportunities.

- Color Management: Advanced color management features ensure accurate color reproduction, allowing you to achieve consistent results across different prints.

- Upgradability: Choose a sublimation machine that is upgradable, allowing you to add new features or accessories as your business grows. This flexibility saves both time and money in the long run.

- Integrated Heat Press: Some advanced sublimation machines come with an integrated heat press, eliminating the need for a separate machine. This convenient feature saves space and streamlines the printing process.

By carefully considering these factors and features, you can select the right sublimation machine to meet your specific needs and achieve outstanding results in your sublimation printing endeavors.

Substrates Compatible With Sublimation Machines

Are you looking for sublimation machines that work well with various substrates? Look no further! Our machines are compatible with a wide range of materials, allowing you to create vibrant and long-lasting prints easily.

Sublimation machines are a versatile tool for transferring vibrant and long-lasting designs onto various materials, known as substrates. The range of substrates that can be used with sublimation machines is vast, catering to different industries and personalization needs. In this blog post, we will explore some popular substrates compatible with sublimation machines.

Fabrics And Apparel

Sublimation printing has revolutionized the world of fabrics and apparel, allowing for exceptional print quality and durability. With the right sublimation transfer paper and ink, you can effortlessly create custom designs on polyester-based garments, including t-shirts, hoodies, leggings, and more. Polyester blends with at least 50% polyester content can also be sublimated, providing endless possibilities for personalized fashion and promotional wear.

Mugs And Drinkware

Add a touch of creativity to your morning routine or elevate your gift-giving game with sublimated mugs and drinkware. Sublimation machines enable you to transfer designs onto ceramic, porcelain, and even coated metal mugs, ensuring vibrant and dishwasher-safe results. Whether it’s a photo collage, a witty quote, or a company logo, sublimation printing delivers stunning and long-lasting designs that won’t fade over time.

Phone Cases And Accessories

Sublimation printing makes personalizing your phone case and accessories easier than ever. From protective phone cases to laptop sleeves and even portable chargers, sublimation machines allow you to imprint eye-catching designs on various materials, such as hard plastic, rubber, and fabric. With the ability to print intricate details and vibrant colors, sublimated phone cases and accessories make a statement and protect your devices simultaneously.

When it comes to substrates compatible with sublimation machines, the possibilities are endless. These are just a few examples of the various materials you can customize with vibrant and long-lasting designs. Whether you’re running a personalization business or simply looking to add a unique touch to your everyday items, sublimation machines offer the tools you need to bring your creative vision to life.

Sublimation Printing Techniques

Sublimation printing is a versatile and popular method for creating vibrant, high-quality designs on various materials. Two main techniques are used in sublimation printing: Dye-Sublimation Printing and Transfer Sublimation Printing. Each technique has its own unique process and applications. Let’s explore them in detail:

Dye-sublimation Printing

Dye-sublimation printing is a well-known technique used for producing sharp, detailed, and durable prints on fabrics and other materials. It involves the application of heat to transfer dye onto specialized sublimation paper, which is then pressed onto the substrate, allowing the dye to permeate the material’s fibers.

During the dye-sublimation process, the solid dye particles are transformed into gas without going through the liquid stage. The gas molecules then penetrate the substrate’s surface, creating a permanent bond between the dye and the material. This results in prints that are not only long-lasting and resistant to fading but also provide exceptional color vibrancy and accuracy.

Dye-sublimation printing is commonly used to produce personalized apparel, sportswear, home decor items, and promotional products. The technique allows for precise detailing and full-color printing, making it a preferred choice for businesses and individuals seeking to showcase their creativity in a visually striking way.

Transfer Sublimation Printing

Transfer sublimation printing is another popular sublimation technique that offers flexibility and convenience. Unlike dye-sublimation printing, this technique uses specialized sublimation inks to print the design onto a sublimation transfer paper.

Once the design is printed, it is transferred onto the desired substrate using a heat press. The heat activates the inks, turning them into a gas that penetrates the material’s surface, resulting in vibrant and permanent prints. Transfer sublimation printing suits various products, including ceramics, metals, glass, and hard surfaces.

One of the advantages of transfer sublimation printing is the ability to create prints on various substrates without the need for dedicated sublimation-coated materials. This technique provides excellent color saturation and durability, making it a popular choice for producing customized mugs, plates, awards, and other decorative items.

Summary

Both dye and transfer-sublimation printing are effective methods for achieving high-quality prints with excellent color reproduction. While dye-sublimation printing is commonly used for fabrics and textiles, transfer-sublimation printing offers versatility for a wide range of materials. Whether you are creating personalized apparel, home decor, or promotional items, sublimation printing techniques can help bring your designs to life with vibrant colors and long-lasting results.

Common Mistakes To Avoid In Sublimation Printing

Sublimation printing is a popular method used to transfer designs onto various surfaces. While it can produce vibrant and long-lasting results, there are several common mistakes that can hinder the overall quality of the printed output. By being aware of these mistakes and taking the necessary precautions, you can ensure that your sublimation printing projects turn out exactly as intended.

Improper Time And Temperature Settings

One of the most crucial aspects of successful sublimation printing is getting the time and temperature settings just right. Incorrect temperature or time can lead to poor color transfer and image clarity. It’s important to consult the manufacturer’s instructions for the specific sublimation machine you are using and adjust the settings accordingly. Remember that these settings can vary depending on the type of substrate you are printing on. Performing test prints and adjusting the settings based on the results will help you achieve the desired outcome.

Poorly Prepared Substrates

Another common mistake in sublimation printing is not preparing the substrates properly. Failure to adequately clean and prep the surface can result in unwanted blemishes or inconsistencies in the final print. Prior to printing, make sure to clean the substrate thoroughly using a suitable cleaning solution. This will remove any dust, dirt, or oils that could negatively affect the transfer. For certain substrates, such as textiles or fabrics, pre-pressing or pre-treating might be necessary to ensure optimal color absorption. Taking time to prepare your substrates properly will contribute to a higher-quality result.

Summary

Avoiding these common mistakes in sublimation printing will help you achieve superior results. By paying close attention to time and temperature settings, as well as properly preparing your substrates, you can ensure vibrant colors, sharp details, and overall satisfaction with your sublimation prints.

Tips For Successful Sublimation Printing

Sublimation printing is a popular method for transferring vibrant, long-lasting designs onto various items like garments, mugs, and promotional products. To ensure the best results, following some essential tips for successful sublimation printing is important. In this blog post, we will explore the key factors that contribute to a successful sublimation printing process. From prepress preparations to regular maintenance and cleaning, these tips will help you achieve stunning sublimation prints consistently.

Prepress Preparations

Before you start sublimation printing, it’s crucial to get your prepress preparations in order. Here are some important steps to follow:

- Select the Right Substrate: Choose a substrate that is specifically designed for sublimation printing. Different substrates have different properties, so selecting the right one for your desired end product is important.

- Prepare Your Artwork: Ensure your artwork is in a high-resolution format, significantly improving the final print quality. Ideally, use vector-based graphics to prevent any loss of detail or pixilation.

- Calibrate Your Printer: Regularly calibrate your printer to achieve accurate color representation. This will ensure that the colors in your artwork match the final print result.

- Choose the Correct Color Profile: Use the appropriate color profile for your printer and sublimation ink. This will help achieve the desired color accuracy and consistency in your prints.

- Perform Test Prints: Before printing on your desired substrate, it is a good practice to perform test prints on similar materials. This will allow you to make necessary color, saturation, and positioning adjustments.

Maintenance And Cleaning

Regular maintenance and cleaning are essential to keep your sublimation machine running smoothly and ensure high-quality prints. Follow these guidelines:

- Clean the Printer Heads: Regularly clean the printer heads to remove any dried ink or debris. This will prevent clogging and maintain consistent ink flow.

- Use Quality Sublimation Paper: Invest in high-quality sublimation paper that is specifically designed for your printer and ink. This will minimize the risk of paper jams and improve print results.

- Check and Replace Consumables: Periodically check the ink levels, sublimation cartridges, and heat press pads. Replace any depleted or worn-out consumables to ensure optimum performance.

- Inspect and Clean the Heat Press: Check the heat press for any residue or buildup that may affect the transfer process. Regularly clean the heat press with a non-abrasive cleaner to maintain its efficiency.

- Store Sublimation Equipment Properly: When not in use, store your sublimation machine and related equipment in a clean, dust-free environment. Avoid exposing them to extreme temperatures or direct sunlight. Google Maps.

Frequently Asked Questions Of Sublimation Machine

What Machine Is Needed For Sublimation?

A sublimation printer and a heat press machine are needed for sublimation.

What Does A Sublimation Machine Do?

A sublimation machine is a device that uses heat to transfer designs or images onto various materials. It applies heat to convert special inks into a gas, permeating the material and binding with its fibers, resulting in vibrant, long-lasting prints.

What Kind Of Printer Do I Need For Sublimation?

You need a sublimation printer for the sublimation process.

Can My Cricut Do Sublimation?

Yes, a Cricut can do sublimation. It can print on sublimation paper, which can then be transferred onto fabric or other surfaces using heat. Sublimation allows for vibrant, long-lasting designs. Just make sure to follow the specific instructions for sublimation on your Cricut machine.

Conclusion

A sublimation machine revolutionizes the way we print and customize items. Its high-quality results, versatility, and user-friendly features provide endless possibilities for entrepreneurs, hobbyists, and creative individuals. Investing in a sublimation machine opens doors to a profitable business and allows you to turn your artistic visions into reality.

So, don’t wait any longer. Experience the convenience and endless potential of a sublimation machine today.